ATV PRODUCTS

REFLOW SOLDERING

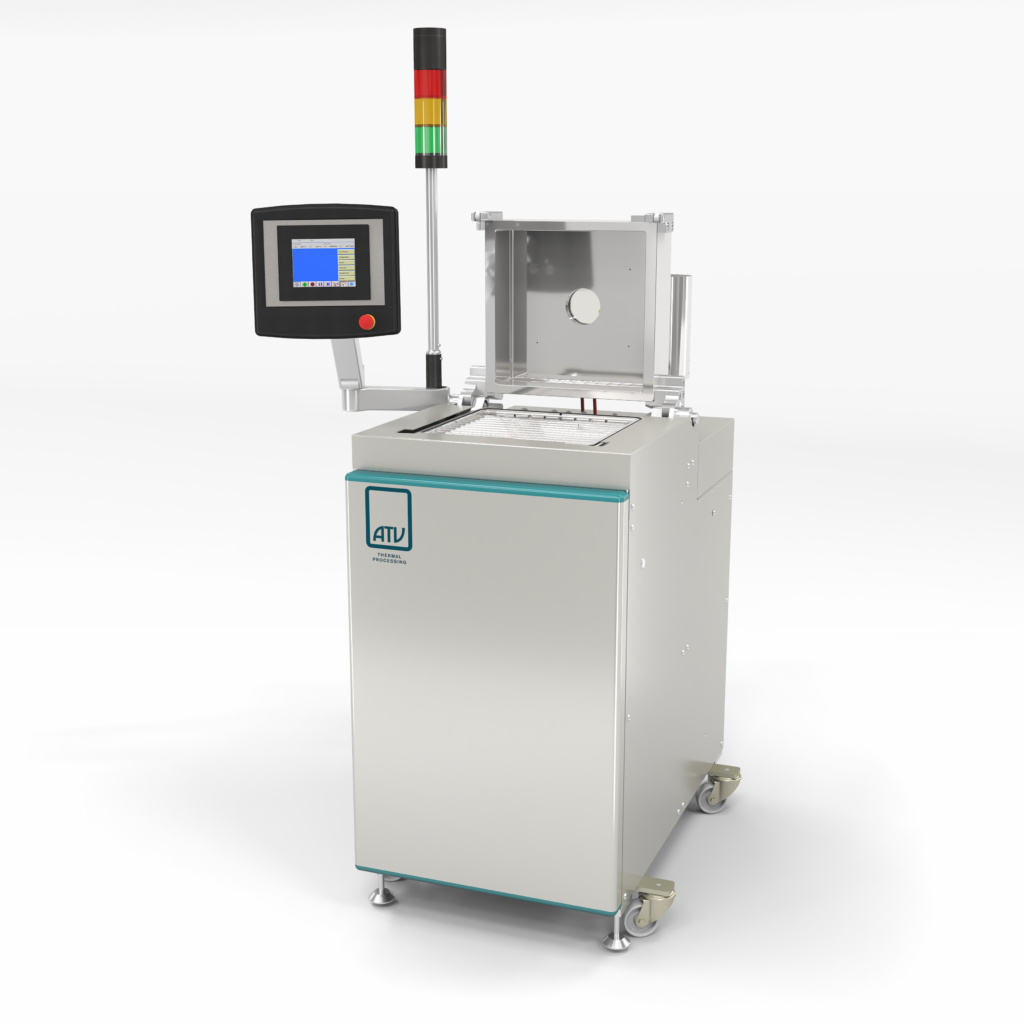

SRO-700 VACUUM REFLOW SOLDERING SYSTEM

TABLE TOP – IR VACUUM REFLOW SYSTEM FOR R&D PURPOSES

The SRO-700 vacuum reflow soldering system is an ideal solution for semiconductor and MEMS applications, , offering 100mm clearance over the heated surface. It can be used for reflow soldering processes, making it a valuable tool for R&D environments. The cold wall chamber principle supports effective thermal management, while the IR lamp heating technology provides consistent heat distribution. The SRO-700 also includes vacuum capabilities and formic acid processes, helping to achieve void-free solder joints and reliable process repeatability.

Facts & Options about our SRO-700 Vacuum Reflow Soldering System

HIGHLIGHTS SRO-700

- Formic Acid Enriched Atmosphere

- Direct IR Heating

- Multiple TC monitoring

- Process temperature 450°C

- Oxygen < 1.0 ppm with purified N2

- 100 steps / recipe program

COMMON APPLICATIONS SRO-700

- IGBT / DBC

- Power Semiconductors

- Sensors

- MEMS Devices

- DIE Attachment

- High Power LED

- Hybrid Assembly

- Flip Chip

- Package Sealing

TECHNICAL DATA SRO-700

depending on system configuration/optionals

- Footprint

- 560 x 800 x 770mm (LxWxH)

- Weight

- 85kg (minimum configuration)

- ChamberHeight

- 96mm

- Heated Area

- 230 x 217mm

- Chamber Lid Open/Closing

- Manual

- IR Heating

- Array of 8 IR lamps in Quartz glass tubes (2 heating zones)

OPTIONS SRO-700

- Fine Vacuum

- High Vacuum

- Closed loop water chiller/heater