ATV PRODUCTS

REFLOW SOLDERING

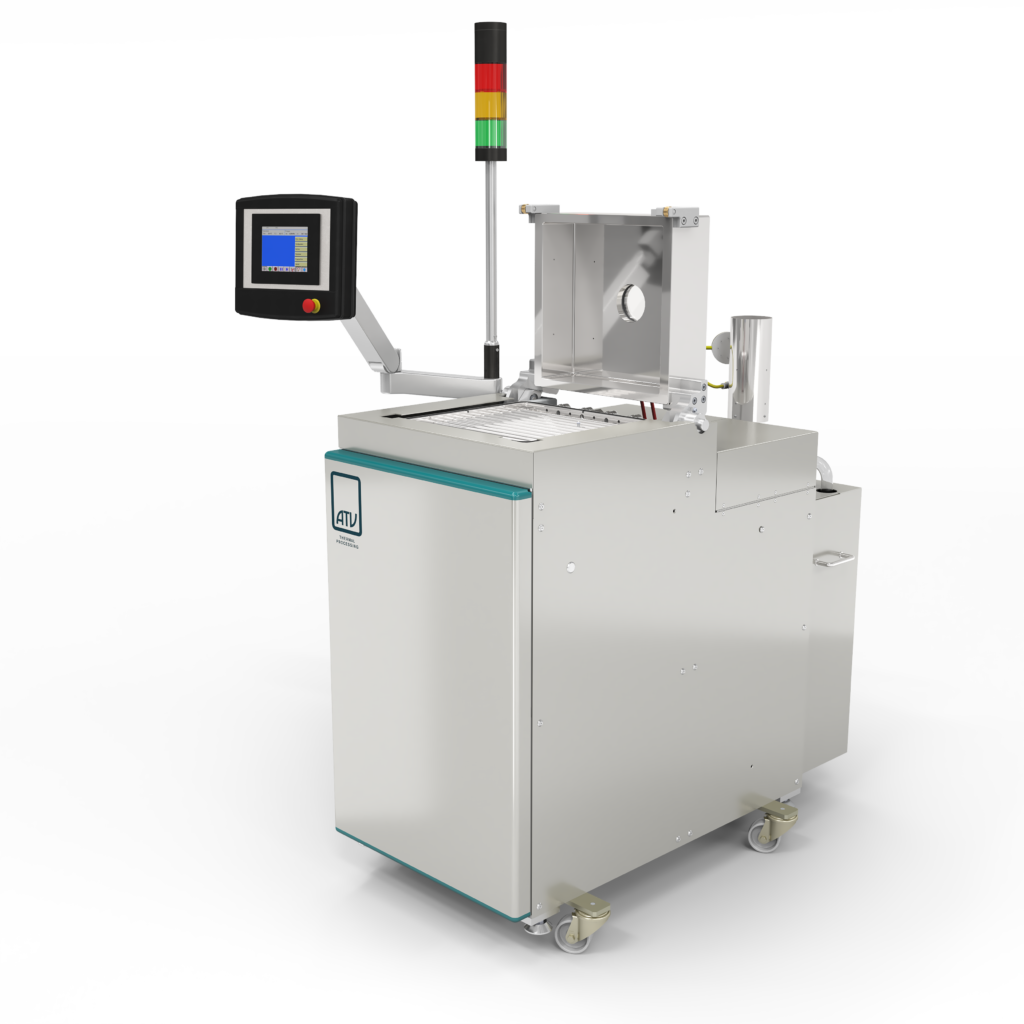

SRO-716 VACUUM REFLOW SOLDERING SYSTEM WITH FLUX MANAGEMENT (SOLDER PASTE)

IR VACUUM REFLOW SYSTEM FOR R&D PURPOSES AND PILOT LINE PRODUCTION

The SRO-716 Solder Paste System is the ideal solution for high-precision and clean soldering processes with solder paste. Based on the proven ATV vacuum soldering technology, it offers reliability and reproducibility for demanding applications in the microelectronics and semiconductor industry. To ensure a contamination-free process chamber, the system is equipped with an integrated flux lid that reliably reduces excess flux residues. A water-cooled condensation separator and a side channel blower efficiently remove flux vapors and ensure a stable process environment. The process chamber is heated by powerful infrared lamps controlled by multiple heating zones with a maximum temperature of 450°C. These ensure homogeneous heating and precise temperature control. Nitrogen (N₂) ensures controlled cooling, while the WinATV software enables precise control and adjustment of all process sequences. The HCOOH step optimizes wetting and ensures excellent soldering quality. With a heated area of 314 x 314mm and a height of 76mm above the heating area, the SRO-716 Solder Paste is suitable for a wide range of electronic components and packages. Ideal for R&D applications and pilot production, this versatile system meets the requirements of modern manufacturing technologies and offers maximum flexibility for specific process requirements.

Facts & Options about our SRO-716 Vacuum Reflow Soldering Solder Paste

HIGHLIGHTS SRO-716-Solder Paste

- Solder Paste and Flux

- Direct IR Heating

- Surface touch TC

- Multiple TC monitoring

- Exchangeable Ceramic Heater Plate

- Process temperature 450°C

- Oxygen < 1.0 ppm with purified N2

- 100 steps / programm

- Automatic lid closing/opening and locking/unlocking

COMMON APPLICATIONS SRO-716-Solder Paste

- Power Semiconductors (IGBT, SiC-MOSFET)

- Sensors

- MEMS

- High Power LED

- MMICs

- CPV, Laser bar

- Die Attachment

- Hybrid Assembly

- Flip Chip

- Package Sealing

TECHNICAL DATA SRO-716-Solder Paste

depending on system configuration/optionals

- Dimensions

- 1196 × 630 x 1830mm (LxWxH)

- Weight

- ca. 245kg

- Working Height

- 1.000mm ± 40mm

- Maximum Product Height

- up to 76mm

- Heated Area

- 314 x 314mm

- Heating Method

- Array of 12 IR lamps in 3 zones

- Temperature

- Process temperature up to 450°C

- Vaccum Level

- 10-2 mbar

OPTIONS SRO-716-Solder Paste

- Custom substrate fixture

- Lift pins